27

(30.5 m). A maximum of three 90° elbows can be used.

Minimum vertical vent is 7 equivalent feet (2.1 m) for

direct vent installations. Standard minimum vertical vent

length is 7 feet (2.1 m). See Figure 25, Figure 28 thru

Figure 30 for differences between standard and direct

vent installations.

3. An AL 29-4C

®

Vent Vertical Vent Terminal must be used at

the termina tion.

4. Maintain a minimum of 6 feet (2.0 m) separation between

the air intake and the exhaust terminals.

HORIZONTAL INSTALLATION REQUIREMENTS

1. The vent system must terminate with the Through-the-Wall

Termination (TWT) kits. Do not locate the terminal within 8 feet

(2.5 m) of an inside corner of a building or adjacent to outside

walls, shrubs or other such objects that may cause adverse

wind conditions in the immediate area.

2. The TWT should be located not less than 12 inches (305

mm) above grade or, in geographical areas where snow

accumulates, no less than 12 inches (305 mm) above antici-

pated snow line. Ensure that TWT is protected against blockage

which may occur during ice build up or snowstorms. The TWT

should terminate at least 3 feet (1.0 m) above any forced air

inlet within 10 feet (3.0 m), except when the forced air inlet

is the combustion air intake of a direct vent appliance. The

TWT should terminate at least 4 feet (1.2 m) below, 4 feet

(1.2 m) horizontally from or 1 foot (305 mm) above any door,

window or gravity air inlet into any building as provided in the

current edition of the nation al fuel gas code ANSI Z223.1.

In addition, a minimum clearance of 4 feet (1.2 m) horizontally

from, and in no case above or below, unless the 4 feet (1.2

m) of horizontal distance is main tained from electric meters,

gas meters, regulators and relief equip ment.

3. This horizontal exhaust vent system must pitch upward toward

the termination at 1/4 inch per foot (21 mm per meter).

4. The TWT is designed such that the building is protected from

degradation by ue gas and condensate. Howev er, if additional

protection is desired, install against the wall a non-corrosive

metal sheet under the TWT.

5. Due to the normal formation of water vapor in the combustion

process, horizon tal terminations must not be located over

areas of pedestrian or vehicular trafc, (i.e., public walkways

or over areas where condensate could create a nuisance or

hazard). This is especially true in colder climates where ice

buildup is likely to occur. A.O. Smith Corporation will not be

held liable for any personal injury or property damage due to

any dislodg ing of ice.

DIRECT VENT INSTALLATION REQUIREMENTS

The labels in the Direct Vent Kit must be afxed to the boiler in

locations specied by the instruction sheet provided in the kit.

The following are requirements for the Air-Intake Terminal (AIT):

1. The Air-Intake System (AIS) must ter minate with the venting

equipment pro vided with the boiler.

2. The AIT should not be located less than 3 feet (1.0 m) below

any exhaust vent within 10 feet (3.0 m).

3. The total horizontal distance of the AIS from the boiler’s

Blower Adapter to the outside of the “AIT” should not be

greater than 100 equivalent feet (30.5 m) of vent pipe nor

less than 3 feet (1.0 m), excluding elbows. A maximum of 3

elbows, equiva lent to 10 feet (3.0 m) each of pipe may be

used.

VENTING SUPPORTS

Care must be taken in the installation of the venting system

that adequate support is maintained throughout the installation

process. When extending more than 10 feet (3.0 m) vertically,

vertical support kits are required once every 10 feet (3.0 m) of

vertical run. Vertical support is also re quired immedi ately after

any transi tion (elbow, tee, etc.) to vertical of over 10 feet (3.0 m)

of run and after any offset in the vertical run.

The support brackets (supplied in the Vertical Support Kit)

are to be secure ly fastened to a solid vertical member of the

building using the appropriate fasteners; i.e., wood screws for

wood framing, machine or tapping screws for structural steel

or masonry anchors for solid masonry. The bracket should be

located so that it will not interfere with any joints of the venting

system. The bottom most support bracket should be located

directly above the rst transition from horizontal to vertical.

If a means of support for the brackets is not available and

horizontal vent sections are present, install hanger straps

(made from non-combustible material) as close to the points of

transition as possible. If the horizontal portions of the vent and/or

vent connector are longer than 6 feet (2.0 m), then install hanger

straps every 6 feet (2.0 m) to support the connector.

Do not rivet or screw the straps to the conduit or other wise

puncture the conduit wall. Instead, wrap an extra loop of strap

around the conduit to hold it in position, or attach the strap to

the center screw of the double wall AL 29-4C

®

vent coupling,

if applica ble.

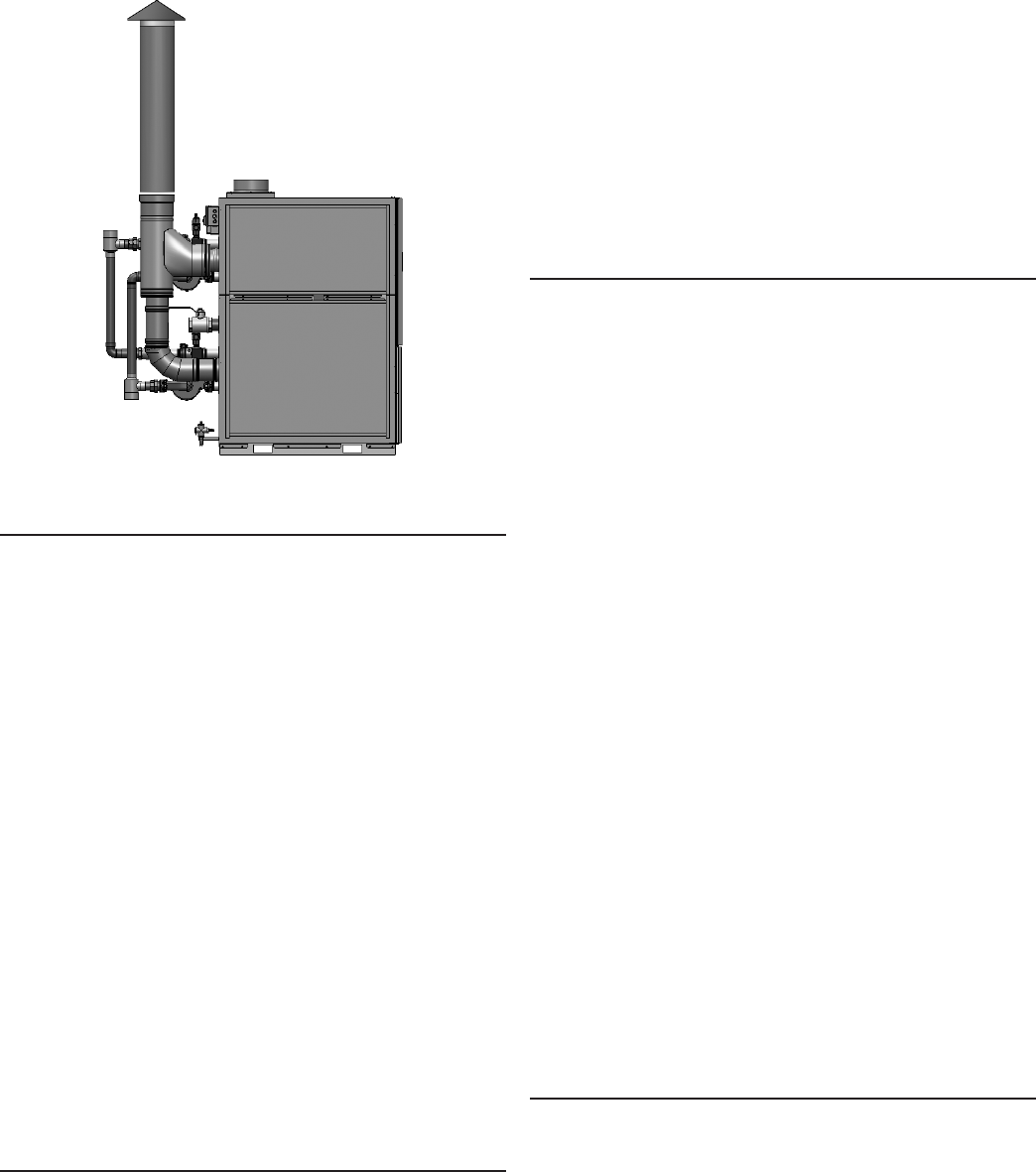

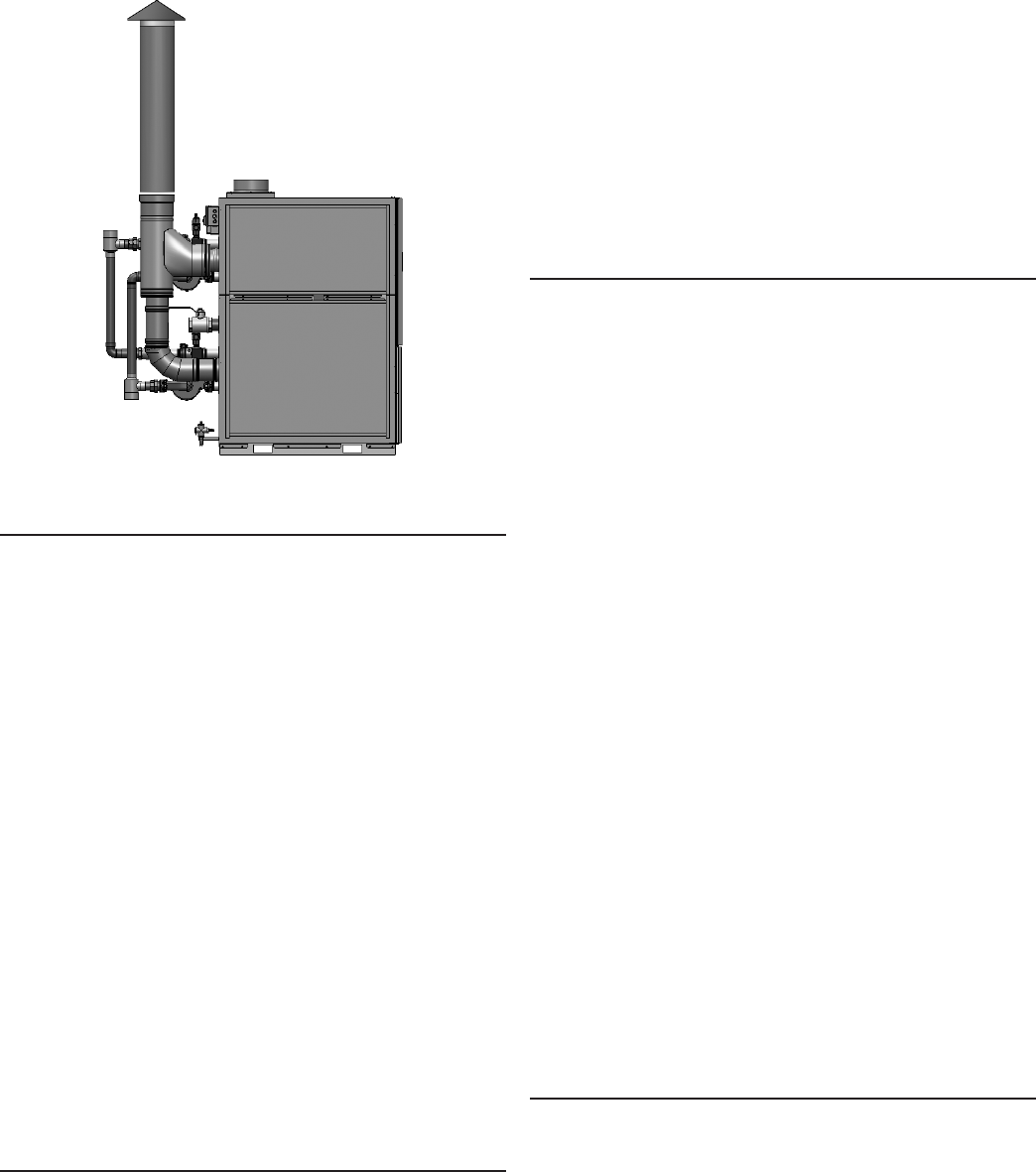

VERTICAL INSTALLATION REQUIREMENTS

1. The vent system must terminate at least 3 feet (1.0 m) and

no more than 6 feet (2.0 m) above the roof line and no closer

than 10 feet (3.0 m) from any wall or verti cal structure. If the

exhaust vent terminal is within 10 feet (3.0 m) of a wall or

parapet, it must extend a minimum of 2 feet (610 mm) above

the wall or parapet, see Figure 25 on Page 28 and Figure

28 on Page 29.

2. For direct vent installations, the total distance of the vent

system from the boiler vent connector to the vertical

vent termination should not exceed 100 equivalent feet

FIGURE 24. PVC/CPVC VENTING - VERTICAL